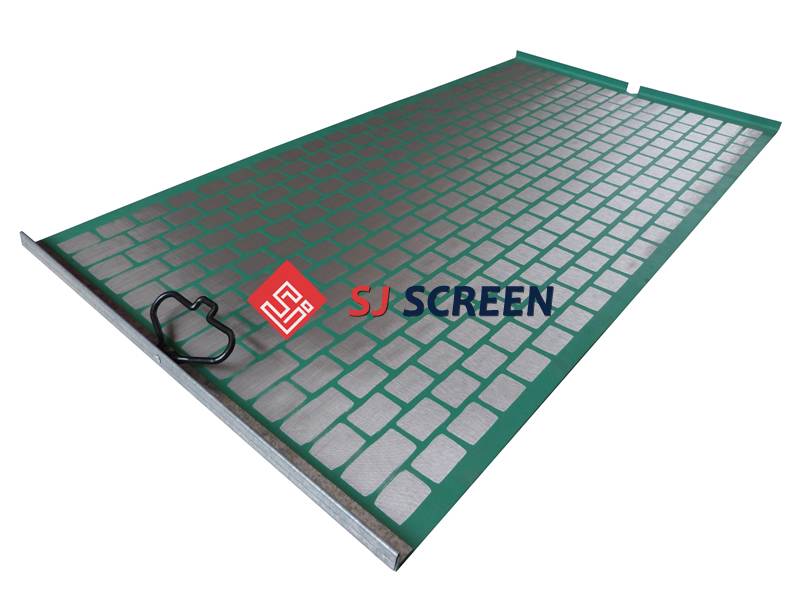

Hook strip flat screen is very popular in the shaker screens filed. This type shaker screen has a simple structure and light weight. Design with a metal lining is easy to replace and repair. Hook strip flat screen has high operational efficiency and good fluid handling capacity. It works by preventing solids from passing the screen.

Compared with hook strip soft screen, hook strip flat screen is more durable and reliable. It can filter out the mud and other impurities in oil. Hook strip flat screen is extensively used as vibrating screen in the oil industry. It performs well in waste management and drilling fluids control.

| The Technical Parameters of Hook Strip Flat Screen | ||||

|---|---|---|---|---|

| Screen Model | Range of Mesh | Dimension (length × width) | Brand & Model of Shaker | Weight (kg) |

| HSFC-1 | 20–325 | 903 × 1155 mm | SWACO BEM-3 |

5.6 |

| HSFC-2 | 20–325 | 697 × 1050 mm | DERROCK FLC 500 Series |

6 |

| HSFC-3 | 20–325 | 1697 × 1053 mm | DERROCK FLC 2000 |

4.2 |

| HSFC-4 | 20–325 | 697 × 846 mm | DERROCK FLC 313M |

4 |

| HSFC-5 | 20–325 | 1050 × 570 mm | Derrock Hyperpool | 4.2 |

| HSFC-6 | 20–250 | 700 × 1165 mm | S250 | 4.6 |

| HSFC-7 | 20–250 | 1186 × 1280 mm | ZX-60 | 9.2 |

This type replacement screen can be specifically designed to fit various shale shakers. Specifications can be customized according to your needs.