Technical Parameter

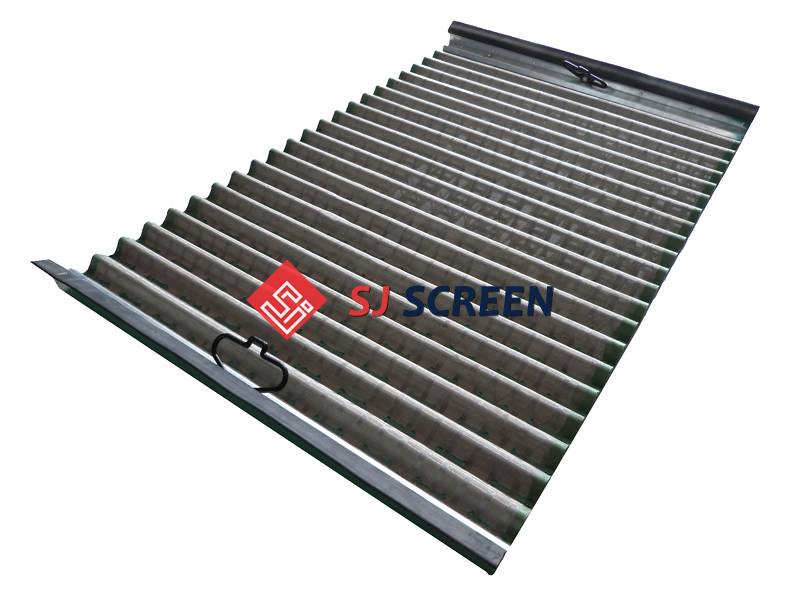

Derrock 500 Wave Shaker Screen replacement is manufactured for all Derrock 500 series shale shakers. Innovative tension fingers and two quick-lock 1/2 turn tension bolts on each screen panel make the installation faster, easier and more reliable. The bottom layer with low mesh counts is waved by coarse wires, then tightly bonded to the backing plate. It offers longer service life and maximizes the separation efficiency.

Adaptable Shale Shaker Model

SJ-Wave 500 shaker screens are used as the substitute screen for:

Performance Parameter

Download Catalogue| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| SJ-Wave 500-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 7.09 |

| SJ-Wave 500-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 7.09 |

| SJ-Wave 500-A200 | DF | API 200 | 1.32 | 73 | 2/3 | 7.09 |

| SJ-Wave 500-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 7.09 |

| SJ-Wave 500-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 7.09 |

| SJ-Wave 500-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 7.09 |

| SJ-Wave 500-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 7.09 |

| SJ-Wave 500-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 7.09 |

| SJ-Wave 500-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 7.09 |

| SJ-Wave 500-A50 | DX | API 70 | 5.17 | 285 | 2/3 | 7.09 |

| SJ-Wave 500-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 7.09 |

| SJ-Wave 500-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 7.09 |

| SJ-Wave 500-A20 | DX | API 20 | 10.88 | 809 | 2/3 | 7.09 |

|

||||||