Technical Parameter

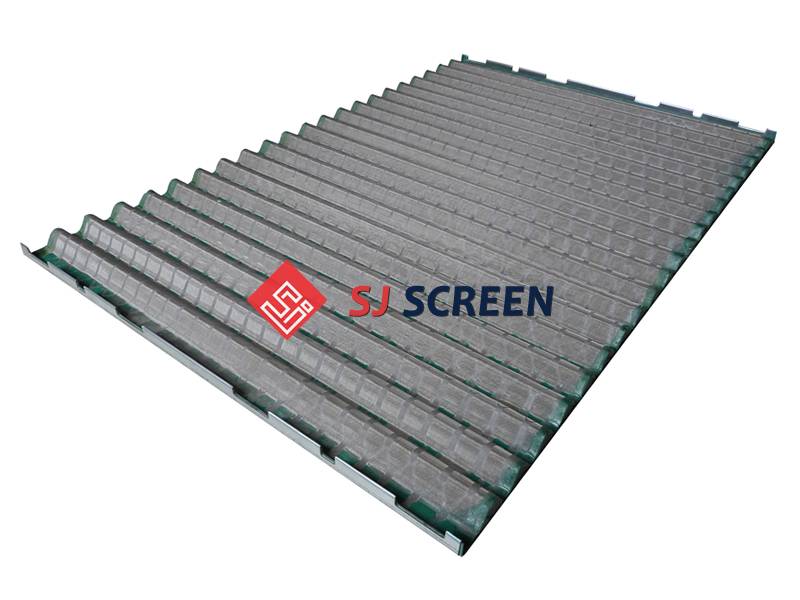

SJ-Wave 2000 shale shaker screen is manufactured based on the innovated design of Derrock Corporation. This type of shaker screen is constructed of multiple layers of stainless steel wire mesh cloth with different densities. Arrange these layers reasonably and exactly, the finished shale shaker screen with revolutionary three-dimensional corrugated screens structure. Pyramid screens offer 125% to 150% usable areas of traditional flat multi-layered screens. And the fluid capacity also has been increased.

Adaptable Shale Shaker Model

SJ-Wave 2000 shaker screens are used as the substitute screen for:

Performance Parameter

Download Catalogue| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| SJ-Wave 2000-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 8.3 |

| SJ-Wave 2000-A270 | DF | API 270 | 0.67 | 57 | 2/3 | 8.3 |

| SJ-Wave 2000-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 8.3 |

| SJ-Wave 2000-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 8.3 |

| SJ-Wave 2000-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 8.3 |

| SJ-Wave 2000-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 8.3 |

| SJ-Wave 2000-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 8.3 |

| SJ-Wave 2000-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 8.3 |

| SJ-Wave 2000-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 8.3 |

| SJ-Wave 2000-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 8.3 |

| SJ-Wave 2000-A60 | DX | API 60 | 4.1 | 268 | 2/3 | 8.3 |

| SJ-Wave 2000-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 8.3 |

| SJ-Wave 2000-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 8.3 |

| SJ-Wave 2000-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 8.3 |

| SJ-Wave 2000-A20 | DX | API 20 | 10.88 | 809 | 2/3 | 8.3 |

|

||||||