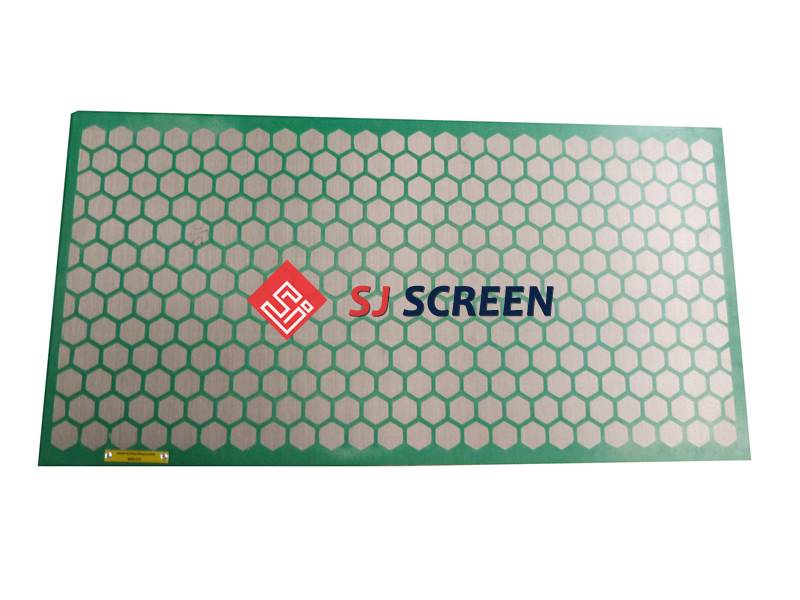

Steel frame shale shaker screen consists of two or three layers of stainless steel wire mesh. Its supporting layer and working layer bonded together to make the screen more durable. The whole screen is divided into many independent small meshes to prevent the excessive extension caused by partial damages. Meantime, the specialized rubber plugs can repair timely. This effectively saves time and reduces disposal costs.

Compared with flat shaker screen and hook strip flat screen, steel frame shale shaker screen has higher strength and better abrasive resistance. The high strength steel frame and supporting grids of the screen forms a reliable and stable structure. Thus greatly increases the shaker screen's loading capacity and operational efficiency.

Replacement screen for VSM 300 Scalping

Replacement screen for VSM 300 primary

Replacement screen for VSM 300 secondary

Replacement screen for BLT-50/LCM-2D shaker

Replacement screen for King cobra

Replacement screen for Mongoose/MEERKT

Replacement screen for D380/D285P shaker

Replacement screen for Kemtron 48 Series

Replacement screen for FSI 5000 Series

| Technical Parameters of Steel Frame Shaker Screen | ||||

|---|---|---|---|---|

| Screen Model | Range of Mesh | Dimension (length × width) | Weight (kg) | |

| SFSS-1 | A16 - 325 | 585 × 1170mm | 12 | |

| SFSS-2 | 16 - 325 | 635 × 1253mm | 13.5 | |

| SFSS-3 | 16 - 325 | 913 × 650mm | 12.5 | |

| SFSS-4 | 16 - 325 | 720 × 1220mm | 17 | |

| SFSS-5 | 16 - 325 | 712 × 1181mm | 17 | |

The replacement screens can be specifically designed to fit various shale shakers. Specifications can be customized according to your needs.