Technical Parameter

Wedge wire screen is a type of filtration screen that is commonly used in industrial applications. It consists of a series of parallel V-shaped wire profiles that are welded to the support rods. The V-shaped wires create a wedge-shaped opening between them, allowing for an efficient flow of fluids while effectively filtering out solids. Wedge wire screens are known for their durability, high strength, and corrosion resistance performance. They are widely used in industries such as water treatment, oil and gas, mining, food processing, and pulp and paper.

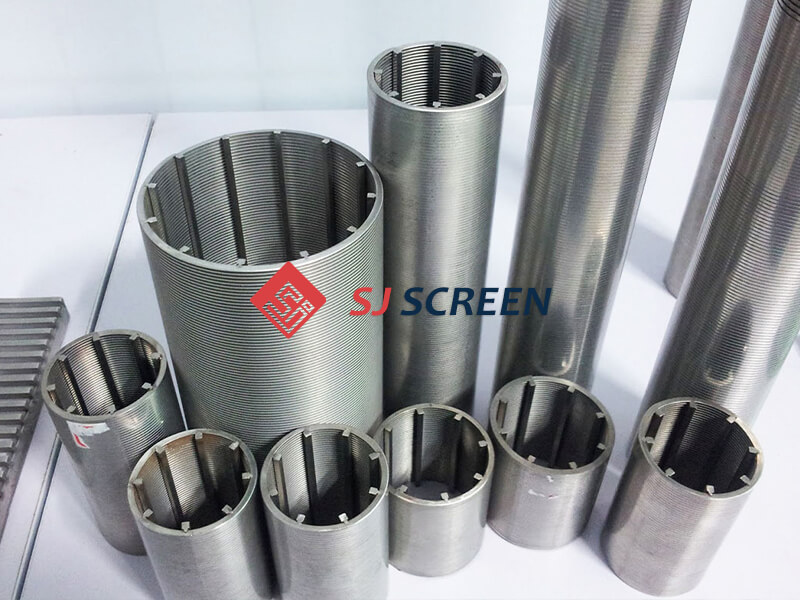

Welded stainless steel wedge wire screen (water well screen) is composed of rods and warp wires. The rod can be round wires, triangular wires, or trapezoid wires. The warp wires are triangular wires (V-shaped wires). Wedge wire screens (water well screens) have a high-strength structure and open area, as well as precise slot sizes. Wedge wire screens (water well screens) are anti-corrosive, safe, and reliable, and have heat resistance performance, good machine capacity, and longer service life. They can be used in many types of media filtering.

Wedge wire screens are formed by V-shaped wire resistance welding with support rods. We are flexible in the selection of materials according to your request. However, carbon steel and stainless steel (302, 304, 304L, 316, 316L, etc.) are the most preferred for the manufacture of wedge wire screens.

Our screens start with high quality raw wires, then they are transformed into a screen that is cut, molded, manufactured, and cleaned. In addition, depending on the area of use and the field of operation, we are able to apply special treatments to different types of wedge wire screens.

Competitive Advantages

The strainer is a kind of filtered water tubing with perforated holes. It can be used with deep well pumps, submerged water pumps, and also used in water treatment equipment, seawater into industrial water and life use water desalination treatment, running water treatment, water softening treatment, petroleum industry (petroleum product terminal filters and chemical acid, alkali liquid filters, ethyl alcohol, etc.), organic solution recycling filters. Continuous slots significantly increase discharge areas, thus providing greater access to water-bearing areas.

We can produce this pipe with a diameter of 80 mm – 550 mm, slot size of 0.1 mm – 10 mm, and length of 50 mm – 5,850 mm.

Wedge wire screen for mine, coal and mineral processing

Wedge wire screen for oil and gas filtration

Wedge wire screen for water treatment