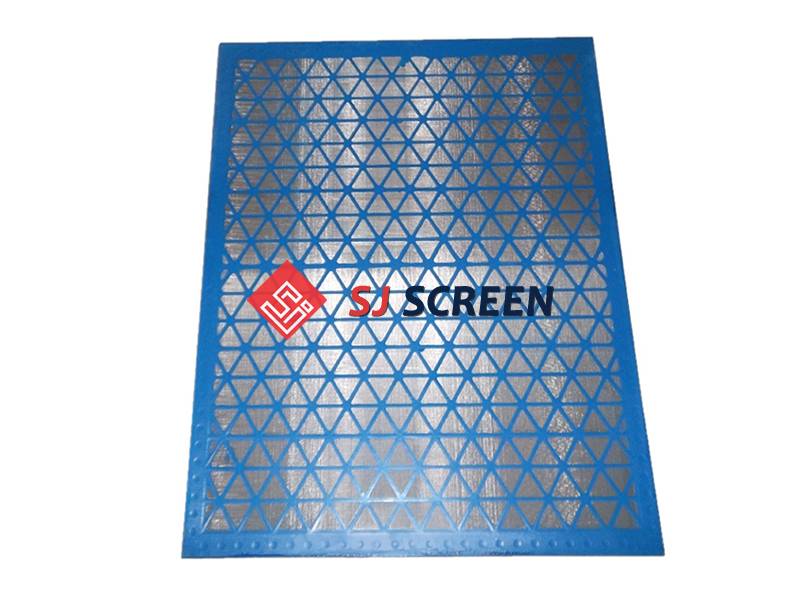

High strength shaker screen is a kind of pre-tensioned replacement screen specifically designed for VSM 300 shale shaker. It has two or three layers of stainless steel wire mesh. The stainless steel wire mesh cloth of high strength shaker screen is fastened directly on the metal frame structure by melting the cloth accurately to the top of the frame.

High strength shaker screen has better wear resistance and higher strength than the normal shaker screen, such as hook strip flat screen, hook strip soft screen and flat shaker screen. This type shaker screen has precise screening effect and high operational efficiency. It is available in various colors, dimensions and sizes. The specifications can be customized according to your specific requirements.

Red high strength shaker screen

VSM 300 shaker screen bonded to steel frame

Green high strength shaker screen

| Technical Parameters of High Strength Shaker Screen | ||||

|---|---|---|---|---|

| Screen Model | Dimension (length × width) | Frame Material | ||

| Model-1 | 902 mm × 686 mm (35.5" × 27") | steel frame | ||

| Model-2 | 676 mm × 940 mm (26 6" × 37") | steel frame | ||

| Model-3 | 203 mm × 686 mm (8" × 27") | steel frame | ||

Other specifications can be customized according to your requirements.