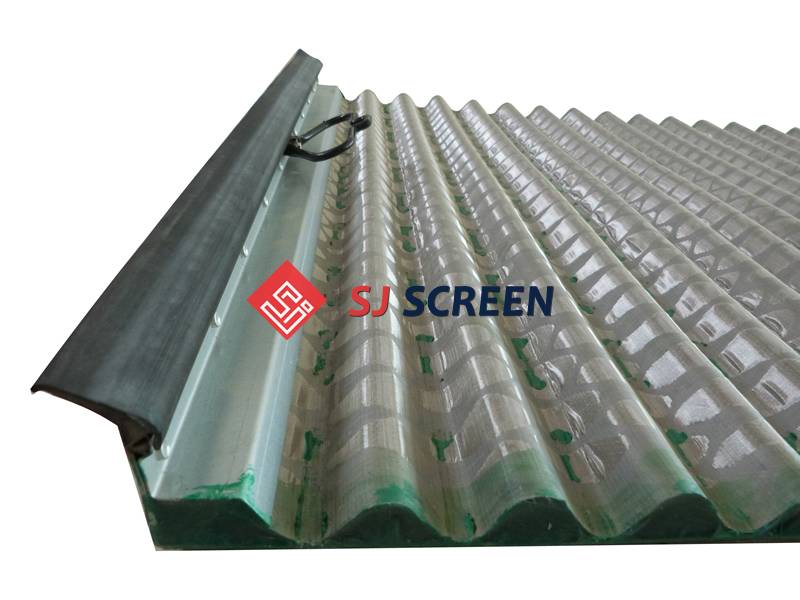

Pyramid shaker screen also called three-dimensional shale shaker screen. It is a new type of replacement screen, which has a single-side screen compression system. This product is an innovation in the shaker screens field. Its mesh sizes are smaller and thinner than that of the steel frame shaker screen. The fine mesh sizes maximize the solids removal capabilities of the screen. It is suitable for various types of shakers, such as, linear motion shale shakers, elliptical and circular motion shale shakers.

Compared with the hook strip flat screen and hook strip soft screen, pyramid shaker screen has more available screening non-blank areas. Test has shown that, due to the screen’s corrugations, the capacity of the shaker gets about a three-fold improvement, while the screen still maintains the equivalent cut-point level of the flat shaker screen. It’s application reduces the number of shakers. Therefore, less space and less cost are realized. Three-dimensional shaker screen is absolutely a superior replacement screen for shale shakers.

| Pyramid Shaker Screen Technical Parameters | ||||||

|---|---|---|---|---|---|---|

| Item | Mesh | Dimension(L × W) | Approx Weight | Screen Layer | Screen Material | Frame Material |

| SJ-P01 | API 20–400 | 1050 × 695 mm | 6.6 kg | 2 or 3 | SS 304/316 | carbon steel |

| SJ-P-02 | API 20–400 | 1053 × 697 mm | 5.6 kg | 2 or 3 | SS 304/316 | carbon steel |

Specifications of pyramid shaker screen can be customized according to your needs.